ADDRESS: New No:9, Old No:5,

North Gopalapuram 2nd Street,

Gopalapuram, Chennai-600 086.

PHONE: 044 28350703, 91-9003078062

EMAIL: kgs.corporation@yahoo.in

PHONE: 044 28350703, 91-9003078062

EMAIL: kgs.corporation@yahoo.in

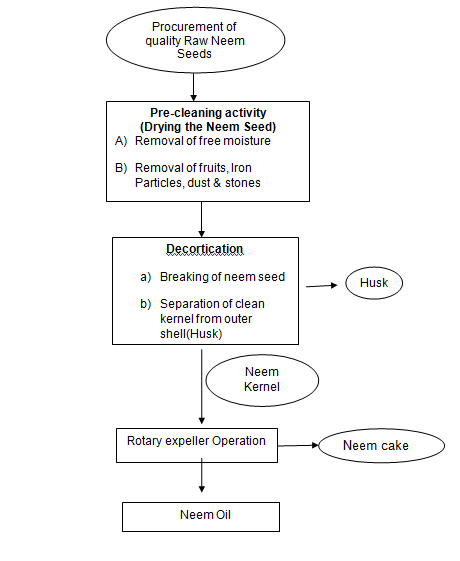

The manufacturing process involves the following steps

Quality raw neem seeds free from fungus and with prescribed quality specifications like less fruit content, less moisture content, and less admixtures like dust, twigs etc is identified and procured from the market and also directly from vendors.

A through water wash is given to the procured raw neem seeds to remove the unwanted external impurities like sand and fine dust. The washed neem seed is then spread on the drying yards and dried by solar drying with uniform exposure to get the moisture content of the neem seed below the specified limit. Then the dried neem seeds are taken through a fruit separating machine wherein the fruits are removed. Further the neem seeds is passed through the magnetic separator to remove any iron materials and then passed through the de stoner to get the stones removed.

The clean and dry neem seed is then passed into a decorticator system. Here the clean neem seed is broken into outer shell and the kernel. Through a winnowing mechanism the outer shells(called neem Husk) are removed from the kernel and bagged separately.

The clean neem kernel is taken into a specially designed rotary expeller machine. The rpm of the machine is controlled in such a way that the temperature of the cake due to crushing process is not raised above a specified limit. The clean kernel cake obtained in flake form is further aerated to remove any excessive heat. After ensuring the temperature of the flakes as per the specified range the flake type kernel cakes is bagged separately while the neem oil is taken into a storage drum for further filtration and packing.